SANITARY BUTTERFLY VALVE SERIES

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

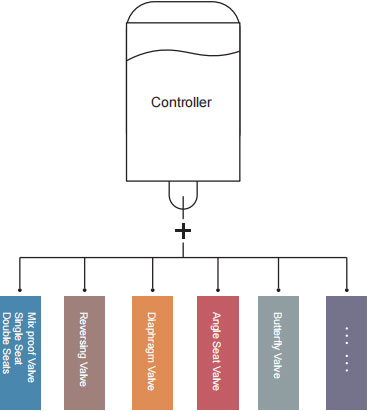

As indispensable valves in sanitary process pipe systems, sanitary butterfly valves are also the most basic valves.

The connection method for butterfly valve: butt-welding butterfly valve, external thread butterfly valve, clamp butterfly valve and wafer three-piece butterfly valve, which is suitable for the standard pipes of ISO, DIN, IDF and SMS.

BV staitary butterfly valve can be equipped with pneumatic stainless steel cylinder actuator, and the actuator diameter is 85mm, 108mm and 133mm; the aluminum pneumatic single-function and double action actuator and electric actuator are optional. The optional accessories, valve location feedback and adjustable positioning device realize the automatic intelligence control. It's applied for the stainless steel pipe system in the fields of beer, beverage, juice and pharmaceutical industry.

- Welding

- Clamp

- External thread

- Three-piece wafer

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

As the upgraded products, based on the unique design of butterfly disc and better sealing, the

leakproof butterfly valve can discharge the medium from the sewage cleaning access under

the conditions of leakage, produce the function of leakproof and cavity cleaning in the process

pipe, two options of manual and pneumatic drive can be selected, the pneumatic drive and

adjacent switch can be selected if it's connected to the transmission data in self-control center.

It's applied for the stainless steel pipe system in the fields of beer, beverage, juice and food

industry etc.

Manual leakproof butterfly valve

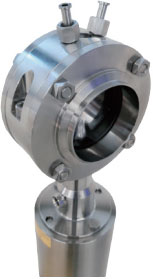

FORGING SANITARY BALL VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

The sanitary forging ball valve is broadly applied for the industries of biological fermentation, wine, fine chemicals and soon, which can completely replace the industrial ball valve, sanitary welded tube seamless joint can be greatly used for the engineering projects by adopting sanitary flange with extended spindle, it can improve the whole project quality and meet the sanitary requirements.

TECHNICAL PARAMETER

- Normal diameter: DN15~DN100 1/2”-4”

- PN: 10 bar

- The highest application pressure: 8 bar

- Temperature range: -10°C~+150°C

CONNECTION METHOD

Welding, clamp, external and sanitary flange

DRIVING METHOD

Welding, clamp, external and sanitary flange

SMALL VALVE BODY FORGING SANITARY BALL VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

It can be used for the material handling. The application scope refers to the fields of food, beverage processing as well as pharmacy and chemical industries, etc. The completely penetrating cavity design won't produce any liquid

resistance, so it's the optimum choice to handle the liquid with viscosity or particulate matter.

TECHNICAL PARAMETER

- Normal diameter: DN15~DN100 1/2”-4”

- PN: 10 bar

- The highest application pressure: 8 bar

- Temperature range: -10°C~+150°C

|

CONNECTION METHOD

Welding, clamp, external screw and sanitary flange

DRIVING METHOD

Manual, pneumatic, electric and hydraulic |

Forging pneumatic three-way ball valve

Forging straight-through ball valve

THREE-PIECE BALL VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

The connection method for three-piece ball valve is diversified, which refers to internal screw, industrial thick wall pipe welding, sanitary pipe thin wall pipe welding(the extended automatic welding can

be provided combined with automatic welding machine), sanitary pipe quick assembly, sanitary pipe and flange, international pipe and flange, etc.

Ball valve body can be equipped with international standard ISO high platform and locking device, can be equipped with pneumatic actuator, electric actuator, can add valve position feedback and

mechanical positioner and intelligent positioner, can meet the needs of various process automation control.

APPLICATION RANGE

The three-piece ball valve is suitable for various pipes with the pressure range of PN 1.0Mpa-6.4Mpa, operating temperature of -29°C~180°C(the sealing ring is reinforced PTFE) or -29°C~300°C(the sealing ring is PPL), which is used to cut of for connect the medium in the pipe. Different selection of medium and connection modes can be broadly applied in the fields of oil, chemicals, metallurgy, powerplant, water, food, Chinese patent medicine extraction, beverage, protein, biological fermentation, HVAC and soon.

Pneumatic three-piece ball valve

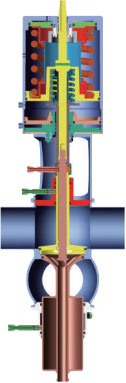

SAFETY VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

With simple structure, beautiful appearance, quick adjustment and adjustable pressure control, the safety valve

can be randomly adjusted within the full range, the liquid input direction shall be noticed during the installation

and the inverted input is forbidden, which can be broadly applied in the industries of food, beverage, dairy prod-ucts, beer and soon.

TECHNICAL PARAMETER

- Working pressure:≤ 8bar

- Normal diameter:DN25~DN100

- Sealing material:EPDM

- Temperature range:-10°C~+100°C

- Working medium:liquid, gas

Sanitary ball type safety valve

Pressure regulating valve with scale

TANK BOTTOM VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

Non-detention tank bottom valve replaces(up and bottom extension) replaces the baiting valve, the process technical design and production process of

baiting valve in early stage is very rough, which can only be suitable for the initial stages that the biological fermentation production process doesn't have higher requirements, it can't completely satisfy the higher microbial requirements of the 21st century on biological fermentation of sanitary food, so we perform oriented research on the sanitary bating valve(non-detention tank bottom valve) by means of our professional application on sanitary valves,the

smooth internal structure can meet the food requirements of Ras 0.8pmby adopting the stainless steel forging valve body combined with currently latest

process of sanitary valve, which is one of the first choices for the bottom valves in the industries of modern biological fermentation, starch and soon.

CONNECTION METHOD

- Flange

- The connection method to pipe or equipment can be in accordance with various flange standards

CHECK VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

Sanitary check valve is indispensable in the process pipe, it prevents the liquid from

back liquid, especially the ball type check valve developed by us is with less resistance

and liquid loss, which is the first choice for check valves in process pipe, all of check

valves are with abundant connection methods, for example, the sanitary flange obtains

the characteristics of proof pressure and convenient assembly, which can be separated

to clamp, welding and external screwing.All of these valves can be manufactured as per

DIN, ISO, IDF, SMS and 3A standard.

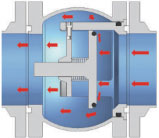

DOUBLE-SEAT DUAL-SEALING

FORGING MIXING PROOF VALVE

INTRODUCTION TO

THE FUNCTIONAL CHARACTERISTICS

It plays a crucial role in the centralized control of intelligent automation, for the mainstream production technology of high-end double-seat dual-sealing

forging anti-mixing valve in the international industry, all of the valve bodies are forged by raw steel based on the finish turning molding techniques of

CNC, we are devoted to improving the relevant techniques and walking together with the internationally mainstream high-end valves.

The forging and manufacturing process of raw steel obtains strong rigidity and it can bear strong acid-base under the temperature function, the whole

set import of sealing ring in key accessories make valves can stably operate at the process pipe for along time. It has been broadly applied in the

industries of dairy products, beer, beverage, condiment, and biological fermentation, etc.